Products Description

Stainless Steel Wire Mesh

Stainless steel mesh, also referred to as stainless steel wire mesh or stainless steel wire cloth, is a type of netting product fabricated from stainless steel wire as the raw material.

Material:SUS302, 304, 304L, 316, 316L, 310, 310S, etc.

Stainless steel mesh specification sheet

Plain Weave | |||

Mesh per inch | Wire Dia. (MM) | Opening (MM) | Material (AISI) |

1mesh × 1mesh | 2 | 23.37 | 304 or 316 |

2mesh × 2mesh | 1.6 | 11.1 | 304 or 316 |

3mesh × 3mesh | 1.37 | 7.09 | 304 or 316 |

4mesh × 4mesh | 1.6 | 4.75 | 304 or 316 |

4mesh × 4mesh | 1.19 | 5.16 | 304 or 316 |

5mesh × 5mesh | 1 | 4.04 | 304 or 316 |

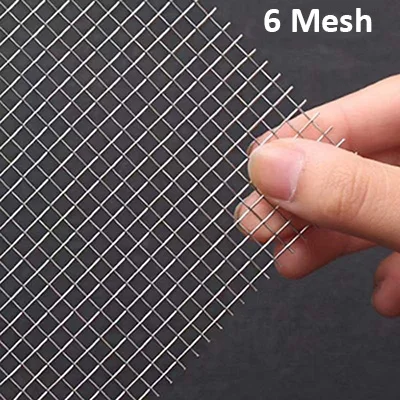

6mesh × 6mesh | 0.89 | 3.35 | 304 or 316 |

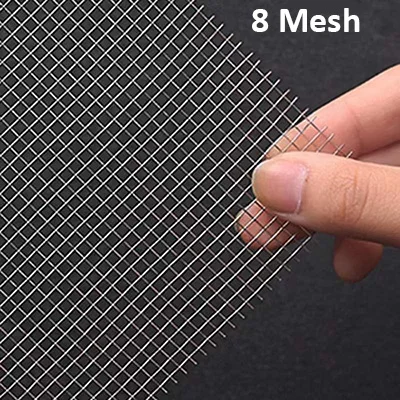

8mesh × 8mesh | 0.71 | 2.46 | 304 or 316 |

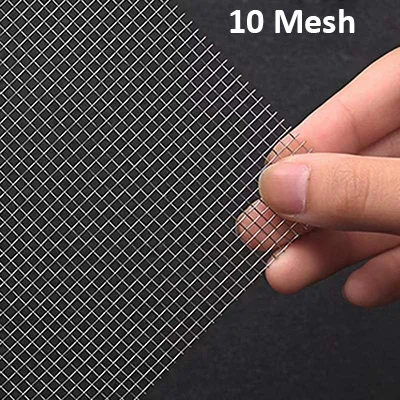

10mesh × 10mesh | 0.64 | 1.91 | 304 or 316 |

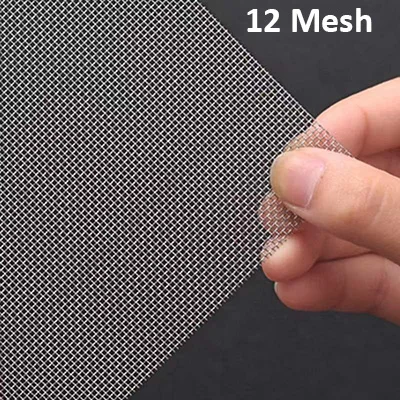

12mesh × 12mesh | 0.58 | 1.52 | 304 or 316 |

12mesh × 12mesh | 0.5 | 1.6 | 304 or 316 |

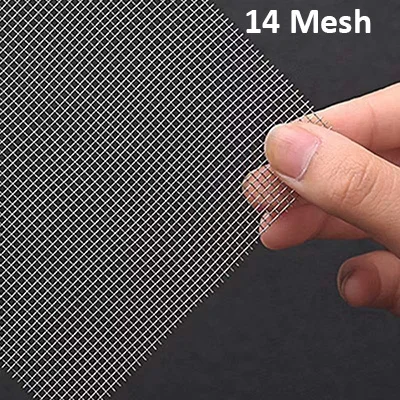

14mesh × 14mesh | 0.23 | 1.22 | 304 or 316 |

14mesh × 14mesh | 0.5 | 1.3 | 304 or 316 |

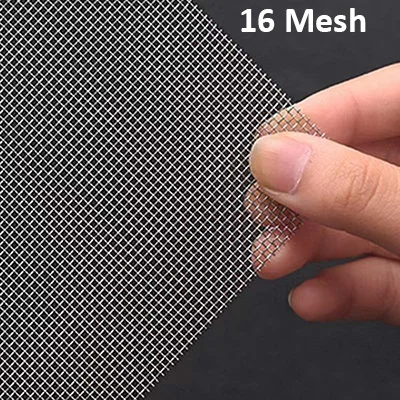

16mesh × 16mesh | 0.45 | 1.13 | 304 or 316 |

18mesh × 18mesh | 0.43 | 0.98 | 304 or 316 |

20mesh × 20mesh | 0.4 | 0.87 | 304 or 316 |

24mesh × 24mesh | 0.35 | 0.7 | 304 or 316 |

30mesh × 30mesh | 0.33 | 0.52 | 304 or 316 |

30mesh × 30mesh | 0.3 | 0.54 | 304 or 316 |

30mesh × 30mesh | 0.23 | 0.62 | 304 or 316 |

35mesh × 35mesh | 0.28 | 0.45 | 304 or 316 |

40mesh × 40mesh | 0.25 | 0.38 | 304 or 316 |

40mesh × 40mesh | 0.23 | 0.4 | 304 or 316 |

50mesh × 50mesh | 0.23 | 0.28 | 304 or 316 |

50mesh × 50mesh | 0.2 | 0.31 | 304 or 316 |

60mesh × 60mesh | 0.18 | 0.23 | 304 or 316 |

60mesh × 60mesh | 0.18 | 0.25 | 304 or 316 |

70mesh × 70mesh | 0.165 | 0.2 | 304 or 316 |

70mesh × 70mesh | 0.12 | 0.24 | 304 or 316 |

80mesh × 80mesh | 0.165 | 0.2 | 304 or 316 |

80mesh × 80mesh | 0.14 | 0.15 | 304 or 316 |

90mesh × 90mesh | 0.12 | 0.16 | 304 or 316 |

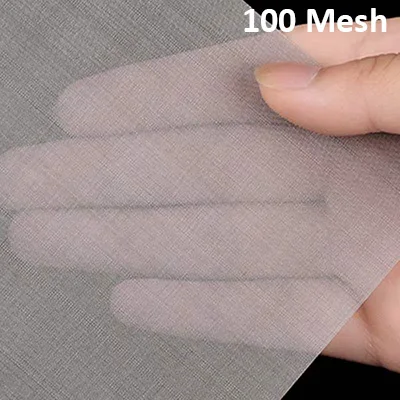

100mesh × 100mesh | 0.11 | 0.14 | 304 or 316 |

100mesh × 100mesh | 0.1 | 0.15 | 304 or 316 |

100mesh × 100mesh | 0.09 | 0.17 | 304 or 316 |

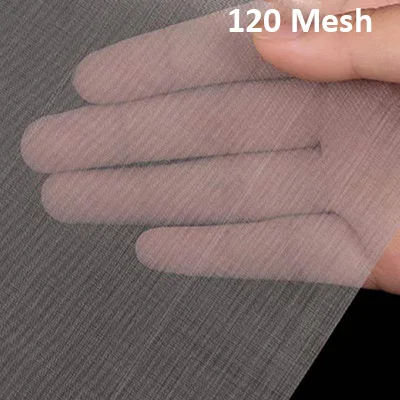

120mesh × 120mesh | 0.09 | 0.12 | 304 or 316 |

150mesh × 150mesh | 0.063 | 0.11 | 304 or 316 |

180mesh × 180mesh | 0.053 | 0.09 | 304 or 316 |

200mesh × 200mesh | 0.053 | 0.07 | 304 or 316 |

250mesh × 250mesh | 0.04 | 0.063 | 316 |

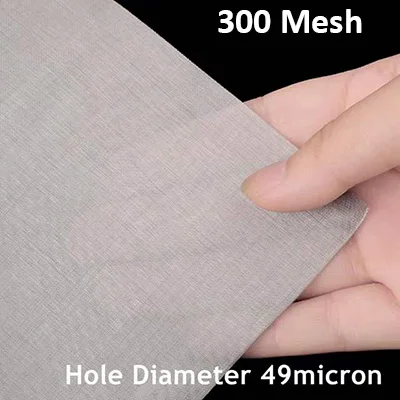

300mesh × 300mesh | 0.04 | 0.044 | 316 |

325mesh × 325mesh | 0.035 | 0.043 | 316L |

350mesh × 350mesh | 0.03 | 0.042 | 316L |

400mesh × 400mesh | 0.03 | 0.033 | 316L |

450mesh × 450mesh | 0.028 | 0.028 | 316L |

500mesh × 500mesh | 0.025 | 0.026 | 316L |

635mesh × 635mesh | 0.02 | 0.02 | 316L |

Plain Dutch Weave | |||

Mesh | Wire Dia. (MM) | Normal Opening(μm) | Material (AISI) |

7mesh × 44mesh | 0.71x 0.63 | 315 | 304 or 316 |

8mesh × 60mesh | 0.63 × 0.45 | 300 | 304 or 316 |

22mesh × 64mesh | 0.58 × 0.40 | 280 | 304, 316 or steel |

24mesh × 110mesh | 0.36 × 0.25 | 150 | 304, 316 or steel |

4mesh × 88mesh | 0.50 × 0.33 | 200 | 304, 316 or steel |

30mesh × 150mesh | 0.23 × 0.18 | 100 | 304, 316 or steel |

40mesh × 200mesh | 0.18 × 0.13 | 80 | 304 or 316 |

50mesh × 250mesh | 0.14 × 0.11 | 60 | 304 or 316 |

80mesh × 400mesh | 0.10 × 0.065 | 40 | 304 or 316 |

78mesh × 700mesh | 0.11 × 0.08 | 30 | 304 or 316 |

Twill Dutch Weave | |||

Mesh | Wire Dia. (MM) | Normal Opening(μm) | Material (AISI) |

80mesh × 700mesh | 0.11x 0.08 | 30 | 304 , 316, 316L |

165mesh × 800mesh | 0.07 × 0.05 | 20 | 304 , 316, 316L |

165mesh × 1400mesh | 0.063 × 0.04 | 15 | 304 , 316, 316L |

200mesh × 600mesh | 0.05 × 0.032 | 10 | 304 , 316, 316L |

200mesh × 1400mesh | 0.05 × 0.032 | 10 | 304 , 316, 316L |

250mesh × 1600mesh | 0.05 × 0.032 | 8 | 304 , 316, 316L |

280mesh × 2200mesh | 0.05 × 0.032 | 7 | 304 , 316, 316L |

300mesh × 2100mesh | 0.036 × 0.025 | 6 | 316L |

325mesh × 2300mesh | 0.035 × 0.025 | 4 | 316L |

400mesh × 2800mesh | 0.030 × 0.018 | 3 | 316L |

Reverse Dutch Weave | |||

Mesh per inch | Wire Dia. (MM) | Material (AISI) | |

75mesh × 15mesh | 0.45x 0.5 | 304 , 316, 316L | |

120mesh × 15mesh | 0.35x 0.5 | 304 , 316, 316L | |

132mesh × 17mesh | 0.32x 0.45 | 304 , 316, 316L | |

150mesh × 18mesh | 0.3 × 0.45 | 304 , 316, 316L | |

152mesh × 24mesh | 0.28 × 0.4 | 304 , 316, 316L | |

160mesh × 18mesh | 0.27 × 0.45 | 304 , 316, 316L | |

180mesh × 18mesh | 0.26 × 0.45 | 304 , 316, 316L | |

200mesh × 40 mesh | 0.17 × 0.27 | 304 , 316, 316L | |

260mesh × 40mesh | 0.15 × 0.27 | 304 , 316, 316L | |

300mesh × 40mesh | 0.14 × 0.25 | 304 , 316, 316L | |

Characteristics

- Corrosion Resistance: It demonstrates remarkable resistance to the erosion of various corrosive substances such as acids and alkalis, rendering it highly suitable for utilization in harsh environments.

- High Temperature Resistance: Stainless steel mesh can maintain its stability and mechanical properties at elevated temperatures, exhibiting minimal susceptibility to deformation or melting.

- Wear Resistance: Boasting excellent wear resistance, it can endure the friction and impact of materials during operation, thereby ensuring a prolonged service life.

- Superior Filtration Performance: The mesh features uniform apertures, enabling precise filtration and screening of gases, liquids, and solids, effectively separating substances of different particle sizes.

- Smooth Surface: The surface of the stainless steel mesh is smooth, facilitating easy cleaning and meeting the strict requirements of hygiene and cleanliness as it is not prone to substance adhesion.

High Strength and Toughness: It possesses high tensile strength and toughness, enabling it to bear a significant load without being easily prone to breakage or deformation.

Stainless Steel Woven Wire Mesh Weave Types

- Stainless Steel Plain Weave Mesh: Characterized by a simple structure and uniform mesh, it finds extensive application in general filtration and screening scenarios.

- Stainless Steel Twill Weave Mesh: This type of mesh is more robust, offering enhanced strength and durability, making it suitable for applications demanding higher strength.

- Stainless Steel Dutch Weave Mesh: It features an extremely fine and uniform aperture, enabling high-precision filtration, and is frequently employed in fields such as precision filtration and scientific research.

- Stainless Steel Expanded Mesh: Manufactured by expanding stainless steel plates, it has a diamond-shaped aperture and substantial strength, often being utilized in applications like fences and protective covers.

- Stainless Steel Welded Mesh: Formed by welding stainless steel wires at the intersection points, it has a stable structure and is appropriate for applications necessitating a large mesh size and high strength.

Applications

- Filtration and Separation: It is extensively utilized in the filtration and separation of gases, liquids, and solids within industries such as petroleum, chemical, food, and medicine. For instance, in the petroleum industry, it serves as a mud net; in the chemical fiber industry, it functions as a sieve and filter net; in the food and beverage industry, it is employed for filtering and clarifying liquids.

- Screening and Classifying: Within the mining, building materials, and other industries, it is utilized for screening and classifying ores, sand, gravel, and other materials to separate materials of different particle sizes.

- Protection and Fencing: It can be employed to fabricate protective fences, guardrails, and safety nets, providing safeguarding for buildings, factories, roads, and other locations.

- Decoration and Architecture: It is applied in architectural decoration, such as in the fabrication of decorative screens, railings, and ceilings, imparting beauty and modernity to buildings.

- Other Fields: It also finds application in numerous other fields, such as in the electronics industry for filtering and shielding; in the agricultural industry for greenhouse shading and livestock breeding fences.